Labels according to the type of application

The laminate foil and tubes, made by him, are mainly used for pharmaceutical products, cosmetic, chemical and food industry. There are basically two types of laminate foils: ABL (aluminium barriered laminate) и PBL (polymer barriered laminate) Both are multilayered (in most cases 5 – layered) structures of polymers and co-polymers and a barrier layer. In ABL foils, the barrier is an aluminum layer of a certain thickness (most often 12 or 20, less often 30 micron), while in PBL films the role of a barrier is played by a special polymer layer. The main manufacturer and supplier of foils for laminate tubes is Huhtamaki Germany - a world leader in the production of laminate foils and foils for flexible packaging. Laminate foils allow the application of full color quality printing on the top layer, as well as the application of additional applications such as hot / cold printing. Each laminate tube consists of a body, forehead and cap. In turn, the laminate tubes, produced from the above-mentioned foils are grouped by two main indicators: tube diameter and useful tube volume. Depending on the needs of the client, the most commonly used tubes have diameters ф25, 28, 30, 35, 40 and 50 mm. The useful volume of the tube most often varies from 25 to 250 Additional options for choice for laminate tubes are the type and color of the foreheads and caps used., as well as additional options such as a top-seal applicator.

Labels for the food industry

In the food industry, there are strict requirements for the labeling of goods. Labels should not only be used to identify the product, but also to provide essential information about it (weight, composition, shelf life, etc.). The most commonly used type of labels are paper, as well as those for subsequent application of information – T. the sun. thermolabels.

Labels for direct contact with food

There are cases, in which the labels are not applied to the packaging of the finished product, and directly on it. This requires the input materials, adhesives and inks must meet certain food safety requirements. Labels in the food industry should provide not only comprehensive information on the composition of the product, like that, to help the consumer make an informed choice at the time of purchase, but also to meet the requirements for minimizing negative impacts on food and the environment.

Labels with different industrial applications

This group includes both traditional labels designed for application on various surfaces (glass, wood, metals, plastics), identification labels in transport and logistics, and closely specialized labels, ensuring long-term and reliable identification of chemical products, permanent labeling of machine elements, heat-resistant labels for the purpose of identification of automotive parts, which are heated in working mode. Most often these are synthetic labels with permanent adhesive, which is specially designed for adhesion to difficult surfaces, resistant to temperature fluctuations and a number of chemicals and oil-based substances.

Labels for the cosmetics and pharmaceutical industries

A central element in building the overall image of a cosmetic product is the label. It is the latter, along with the packaging, who have the difficult task of creating the obligatory feeling of good physical condition for these products., health and positive effect on the consumer. This is the sphere, in which the most intensive use of innovative solutions in the field of self-adhesive materials: no - label look, labels for repeated gluing and ungluing with a partial adhesive layer, holographic, metallized labels, labels with additional effects: prege, hot stamping, separated varnish, etc. Labels in the pharmaceutical industry should meet strict durability requirements, sustainability and safety. These are ampoule labels, syringes, infusion banks, labels with one or more detachable parts for simultaneous identification of syringes and attachment to patient records, conventional self-adhesive labels, etc. The small radius and siliconized surfaces combined with the extremely small size of fonts and symbols make pharmaceutical labels a true work of art. Transparent or white, paper or synthetic, monochrome or multicolor - we are able to offer you the right individual solution tailored to all your requirements.

Wine labels

For their production specialized high quality materials are used combined with a wide range of finishing processes: hot stamping, prege, holographic effects, thermosensitive inks, under the influence of which the labels change color when reaching the optimal temperature for wine consumption, etc..

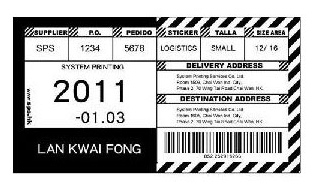

Transport, information, identification and bar code labels

Transport labels are part of the identification system, traceability and targeting of logistics units (goods) along the supply chain. The information on the logistics labels is of two main types: directly readable text and machine-readable texts and graphics, designed for automatic collection of information. Barcodes are one of the safest ways to transmit machine-readable information, while explanatory texts are a universal carrier of basic information, allowing reading at every step of the supply chain. The emerging trend towards increasing the area of retail outlets and the products they offer, requires the creation of barcode labels for the precise identification of items. With the help of barcode identification can be traced the movement of goods from their receipt in the warehouse to the end user. The labels we offer for this purpose are intended for subsequent application of variable information through different printers: label, thermal transfer, thermodirect, jet printers, etc. The key element in their production is durability. They must remain legible and well attached to the product throughout the logistics process, throughout the period of storage of the goods or until the time of purchase.

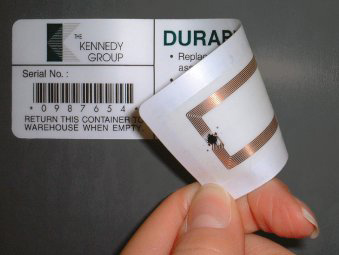

RFID tags

RFID tags, also known as tags or transponders, are used in industry to label individual components or products. They contain a micro control chip and a small antenna, and allow data to be received or transmitted by radio waves, using read and write identifiers. Unlike barcodes, these labels can even be read, when they are stained or scratched from a distance or when there is no direct visibility to them. With RFID tags, the information is embedded in the label itself, which allows the printing of visual information, barcodes and tag coding to be done in one step. RFID printers are used for this purpose. They can be provided in rolls or punched to a certain size.

Special purpose labels

Double-sided / Three-sided labels (2-face, 3-face labels). Through their specific production technology we can double, resp. to triple the printable area of a label, without taking up additional labeling space. Double-sided labels are conventional labels, but with a stamp on the back on the adhesive layer. They are used for products in transparent packaging, the result is a spectacular vision combined with a practical solution to the problem of placing spatial information. Three-sided labels are a conventional self-adhesive label, joined by a printed double-sided label. This technology creates a three-sided label, which, thanks to the adhesive-free zone, can be repeatedly opened and closed by lifting and closing the upper label. They can be made of different types of self-adhesive paper or PP in different combinations of adhesives depending on your specific requirements. They are an ideal solution for products, which require the printing of voluminous information on a limited label area. They are most often used in the automotive and cosmetics industries, but also in nutrition – the flavoring industry for promotional purposes (raffle, awards), as the conditions for the game are placed on both inner sides of the label, and on the upper (visible) part is printed full color graphic image.

No– label look labels ("Invisible" labels)

These are labels with a high degree of transparency of the face material and the adhesive layer, which make an impression, that the design is printed directly on the product packaging, and not on a label. They find everything – widespread in the cosmetics industry, in the production of alcoholic beverages, beer and others.

Sleeves

Slive labels are heat-shrinkable labels, sleeve type, which are placed mechanically or mechanically on a bottle (glass, plastic, metal) or a container of any kind, after that, under the influence of heat, acquire their form. Their advantages lie in the variety of design presentation options (360° from the container), 100 % coverage, possibility to apply voluminous information, all of which together guarantee an outstanding attractive vision of your products. They are widely used in the food and beverage industry. Currently the product does not belong to our portfolio.

Wrap-around labels (circumferential labels)

A brilliant alternative to plum labels. They have their advantages, but are less costly and allow more flexibility in a changing market environment. Very popular choice when labeling carbonated drinks and mineral waters. Currently the product does not belong to our portfolio.

Other labels with special purpose: promotional labels, labels for wet wipes, security labels, "Eternal" labels (durable labels), Braille labels etc. If you are interested in any of the listed categories, please contact us.